Engineers Bollinger & Grohmann offer the structural analysis for the RegoLight project; approaching the project from both large and small scale. At the small scale, sintered simulant regolith is characterized for material integrity after each sintering campaign and is closely coordinated with DRL and Space Applications. The large-scale perspective looks for, and helps to identify, applications for the sintered regolith considering its material characteristics. Mission scenarios are designed with LSG and COMEX laying the foundation for a future moon village, of which the RegoLight brick will be primary building element.

A safety concept is developed by Bollinger & Grohmann, factoring strength of the sintered sample in relation to the total load value a structure on the Moon would be subject; including gravity, change in environmental temperature, live loads, micrometeorites, impact loads, radiation, moonquakes, and internal air pressure that is required to maintain a habitat for long-term human use.

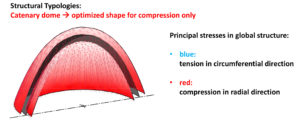

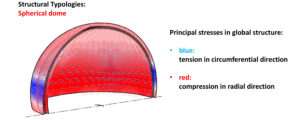

Sintered regolith is strong in compression, brittle in tension and has a weak interlayer bond due to differential thermal strains. These parameters aid the RegoLight team in developing a smart architectural form based on the catenary dome and brick based on interlocking geometry and differentiation.

Large-scale perspective

Application of sintered brick into construction methodology / structural typology

Catenary dome (top) has optimized shape for materials strong in compression, as compared to the spherical dome (bottom)

Small-scale perspective

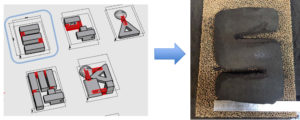

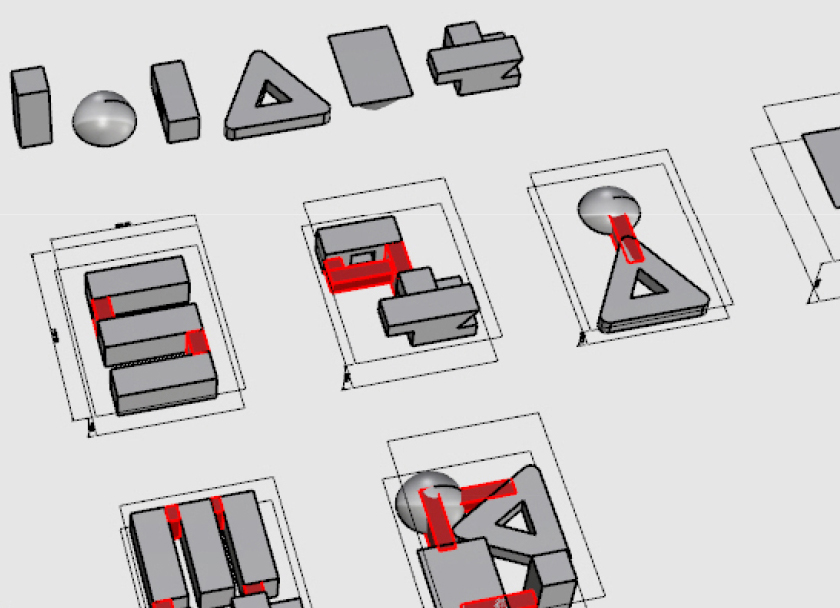

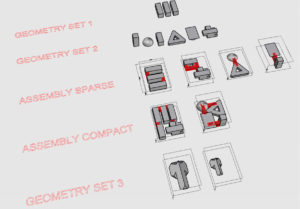

Geometry-sets for testing printer limitations and accuracy

Sintered samples produced from geometry sets – for full material characterization