November 2017

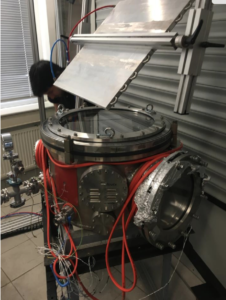

The vacuum chamber was operated by DLR’s solar oven group, and could reach an absolute pressure of

1 mbar. It provided multiple electrical connection points and well as interfaces for water transport into and

out of the chamber. The solar simulator could provide a continuous energy flux of 1.1 MW/m2.

The setup was positioned into the vacuum chamber, and the electrical and water interfaces were

connected. Using the end stops, the zero points of the stages were established, and the

feeding rate and offset was adjusted to achieve optimum spread of regolith powder during operation. After

this, the vacuum chamber was positioned in front of the solar simulator, and the beam spot calibrated so

that it would impact at the correct position. Depressurisation commenced and sintering

started when the vacuum chamber reached a pressure of approximately 2 mbar.

Vaccum chamber set-up, DLR, 2017